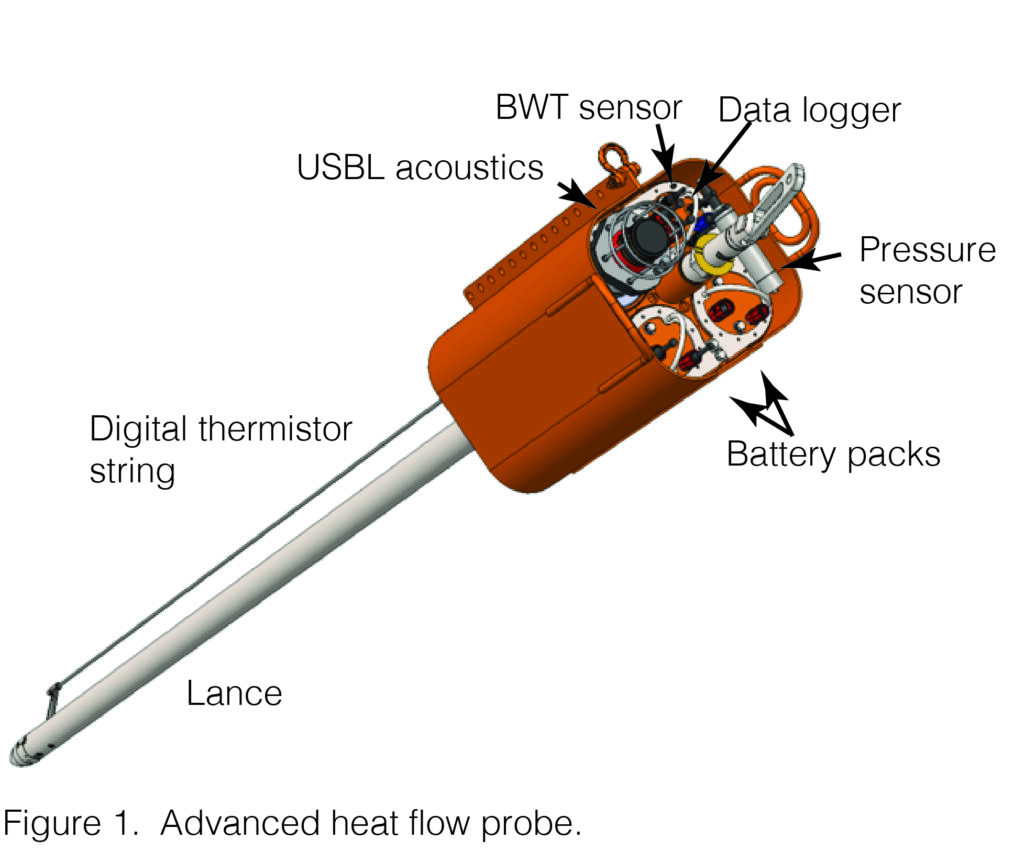

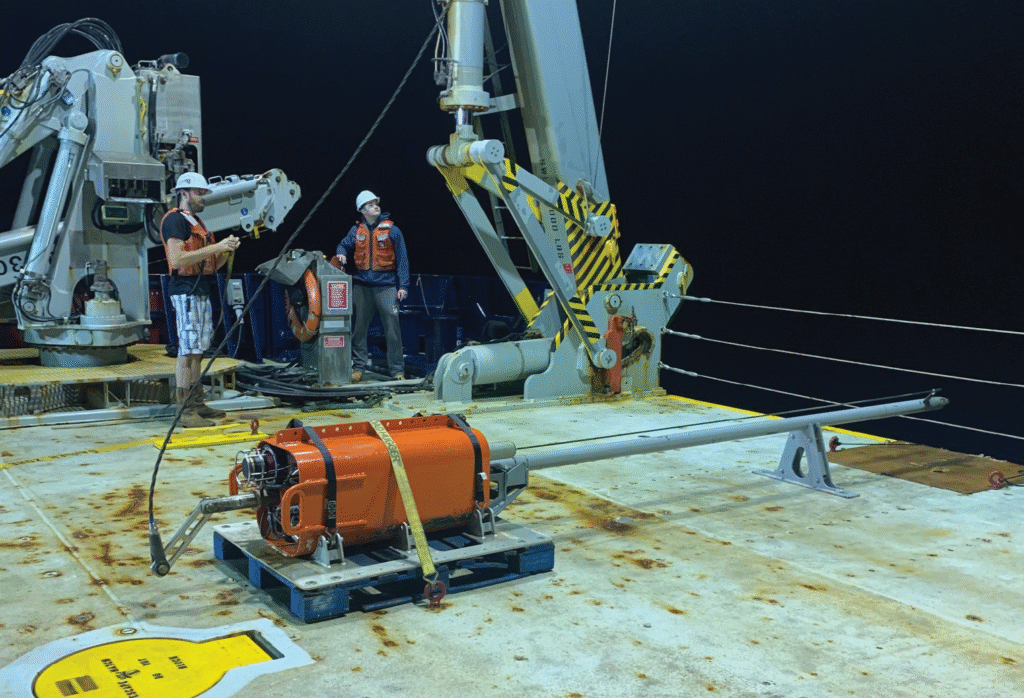

MARSSAM is operating a multi-penetration marine sediment heat flow probe beginning in 2026. The probe, along with MARSSAM technician(s) will be made available to NSF funded science parties if requested. The current configuration uses a 3.5m thermistor string and a 6m option is partially constructed and can be made available pending time and NSF support/approval. The probe was designed by Drs. Rob Harris, Andy Fisher and Maurice Tivey, and built by the CEOAS Machine and Technical Development (CMTD) facility at Oregon State University (OSU). The probe was previously supported through the U.S. Marine Heat Flow Capability program.

The advanced multi-penetration “violin-bow” system allows multiple measurements on a single instrument transit to the seafloor. The design of the violin bow and strength lance provides both the mechanical robustness to withstand repeated insertions and withdrawals from the sediment, and sensitivity needed to make highly accurate measurements. The small diameter sensor tube and thermistor string is held in tension by the lance and is located far enough from the lance to be thermally decoupled from it over the period of the measurement. Advances in electronics and battery technology allow the probe to be deployed for 24-48 hours before retrieval, and ultra-short baseline technology allows the probe position to be routinely positioned with unprecedented accuracy. Acoustic telemetry of the data allows real time monitoring of probe performance and real time survey decisions to be made. The digital 3.5 m thermistor string housing 16 thermistors to determine the thermal gradient and thermal conductivity is measured in-situ at each thermistor using a heat pulse technique. Parameters logged into solid state memory by the system include time, temperature, pressure (depth), water temperature, tilt, and battery voltage. The measurement time for the thermal gradient and conductivity in the seafloor is approximately 15 minutes. Depending mostly on the desired spacing during multi-penetration operations, the mean time between measurement is 1–2 h. The maximum depths for probe operation is 6 km. These attributes make this system adaptable to a wide variety of geothermal environments. This heat flow instrumentation can be operated by a scientific team of 2 or more people, with modest help from an MARSSAM technician. Deployment and recovery of the instrument is handled through the science party, MARSSAM technicians, and MARtechs. Two MARSSAM technicians are required for 24-hr operations. Details of the historic, theoretical and constructional background of multi-penetration probes are given in Hyndman et al. [1979], Villinger and Davis [1987] and Davis [1988].

A multi-penetration heat flow station starts with the lowering of the instrument to the bottom. A 12- kHz pinger is attached to the wire about 75 m above the instrument to monitor the distance between the probe and bottom. The probe is driven into sediments by gravity and temperatures within the sediment are measured with a digital thermistor string. Following collection of data for equilibrium temperatures and thermal gradient, in situ thermal conductivity is measured. A heat pulse is generated with a calibrated current applied to a heater wire that extends along the length of the sensor tube. The temperature decay of the heat pulse gives a measure of thermal conductivity [Lister, 1979]. With the completion of a measurement, the instrument is hoisted 100–500 m above the sediment (depending on intended measurement spacing), the ship is maneuvered to a new position, and the process is repeated. In this manner a navigated transect of heat flow measurement can be obtained relatively quickly. Heat flow measurements can generally be made at a rate of 1-2 hours per measurement, approximately 15 minutes for the actual measurement and 45 to 90 minutes to reposition the ship and probe.

Components

Digital Thermistor String

The digital thermistor string allows more thermistors than previously possible and keeps cross-section of string homogenous. Thermistor boards are 208 mm long, 3.7 mm wide, and 0.8 mm thick. Thermistor boards could be as short as 50 mm, but shorter boards can lead to self-heating. Thermistor boards have a resolution of 1 part in 106. Current through each thermistor board is 5 mA and is minimized to keep self-heating small/negligible. Thermistor boards are networked with the RS485 communication protocol.

Data Logger

Heat flow system is operated using Raspberry Pi 4 model B (Pi4B) with 4 gigabytes of LPDDR SDRAM.

Accelerometer

We incorporate a robust accelerometer that yields tilt and displacement. This is a straightforward way to monitor tilt and probe stability during each measurement. The heat pulse is fired when the accelerometer detects stability for a 7-minute period.

Battery Packs

Sealed lead-acid batteries are utilized in the heat probe and are contained in two independent pressure cases. Batteries can be fully charged within 4.5 hours, and provide a continuous station duration of > 48 hours, including 1 heat pulse per hour.

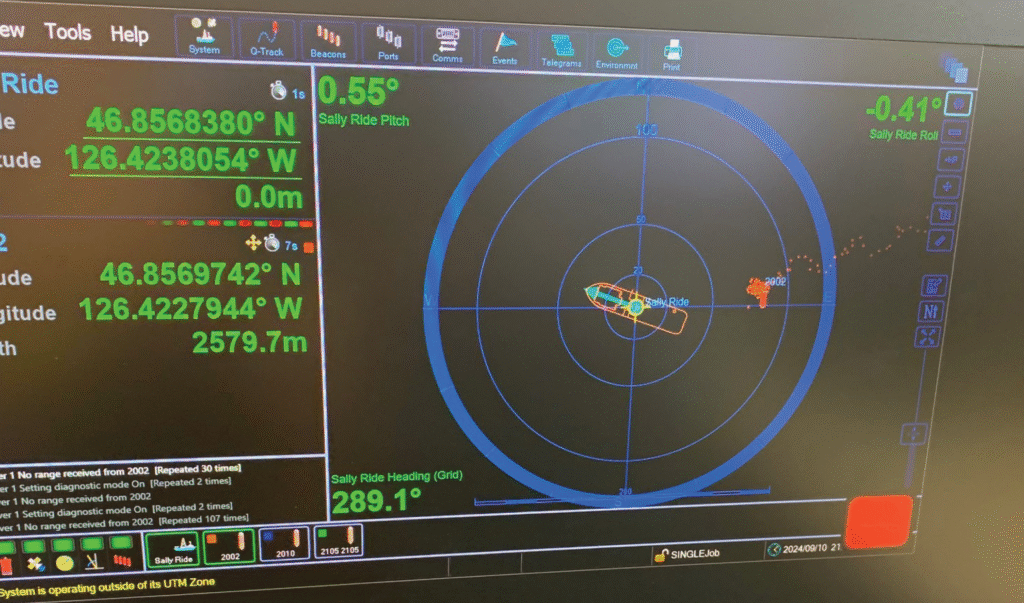

USBL Acoustics

We use a Sonardyne Ranger 2 USBL system for probe locating and real-time telemetry. The Ranger 2 system acoustically transmits probe position (with error <2% of slant range, often <1%) and subset of probe data to monitor probe performance. Knowing the probe position allows greater survey efficiency, allowing the next measurement to begin as soon as the probe is sufficiently close to the ship. This acoustic data link is capable of reliably transmitting data from depths to 6000 meters. The Ranger 2 system is portable and can be configured for use on UNOLS ships.

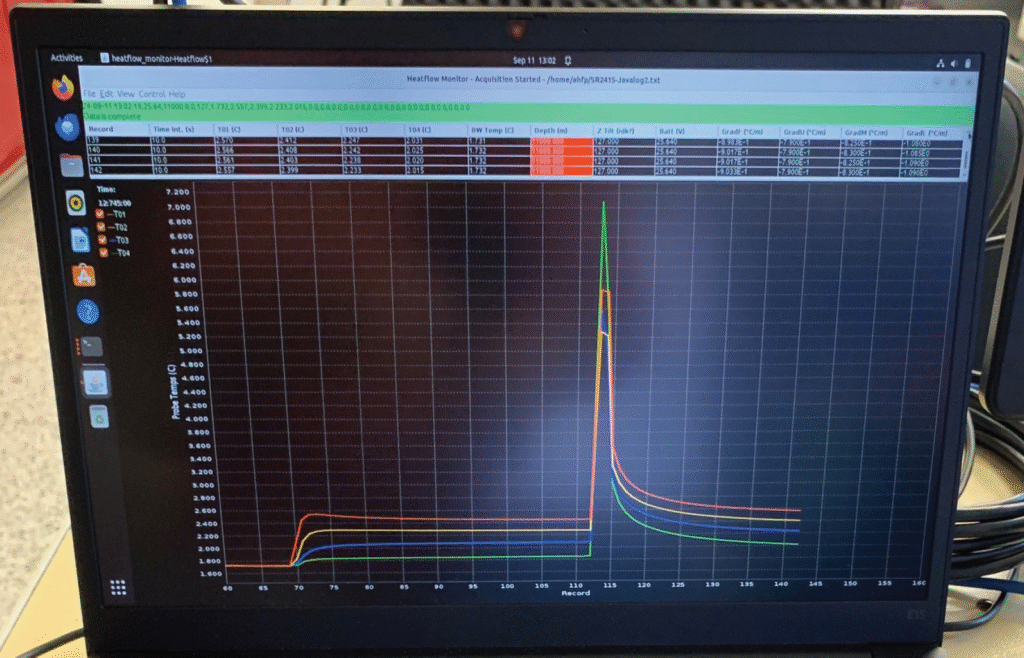

Real Time Data Displays

A subset of data is acoustically transmitted to the ship in real time. This data include battery voltage, acceleration (tilt), pressure (depth), and four thermistors. This data is displayed as text and graphics. These data are enough for the user to ensure the probe is operating properly, allows a quantitative interpretation of the thermal gradient, and on the fly survey decisions.

Data Processing

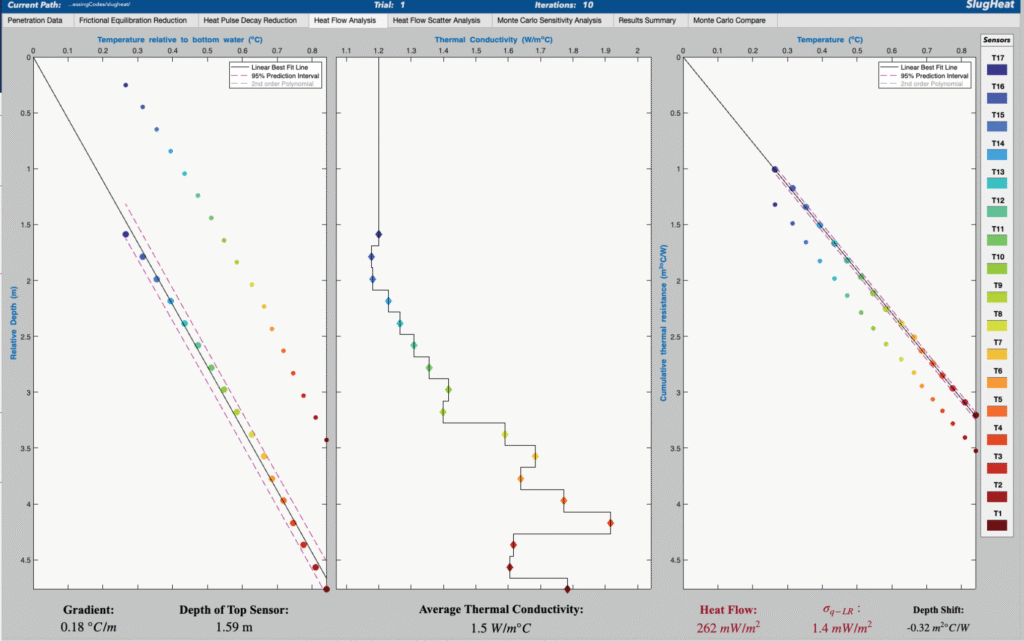

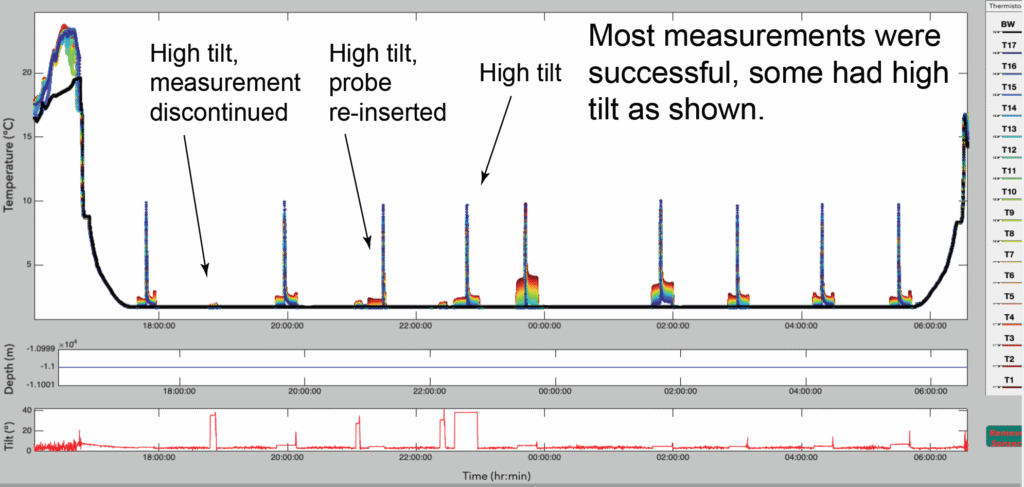

Processing Full Data Set

During a heat flow station, multiple penetrations are made. Temperature data showing each measurement consisting of penetration, frictional heating and relaxation for thermal gradient determination, heat pulse and relaxation for thermal conductivity determination, and pull-out. Data shown below is from heat flow station HM24-1 offshore Washington collected in Sept. 2024 from the R/V Sally Ride. Panels show temperature data (top) showing probe penetrations and heat pulse for thermal conductivity, depth (not working on this deployment), and tilt. Penetration 3 is shown in the following figures.

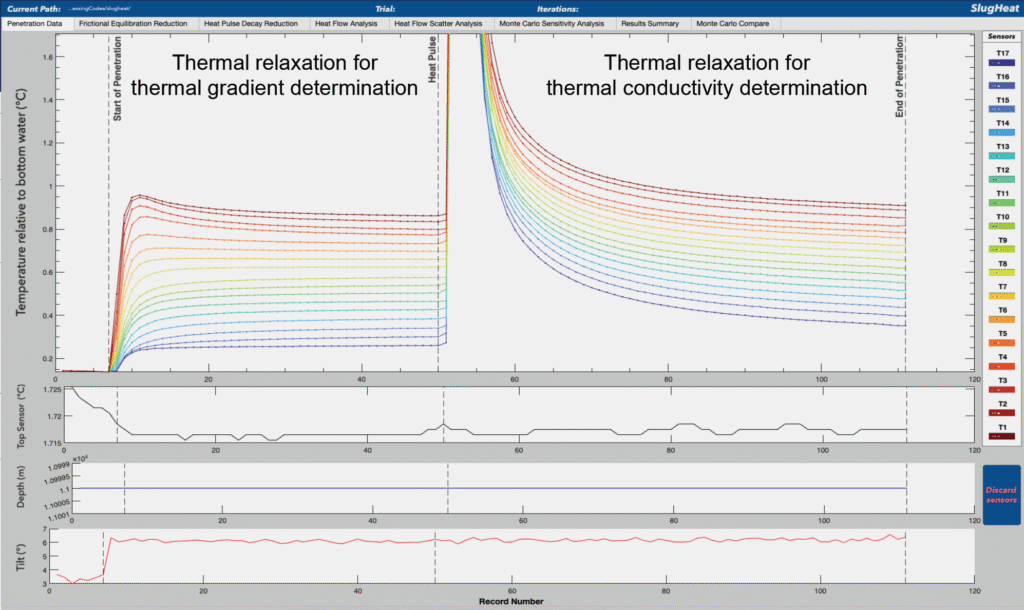

Processing Software: SlugPen and SlugHeat

SlugPen (Dickerson et al., 2024) is a graphically interactive MATLAB program used to parse data from a survey into individual penetration records, including a period of near seafloor equilibration used as a field calibration. Each penetration is processed separately.

SlugHeat (Dickerson et al., 2024) is a graphically interactive MATLAB program that allows a user to plot, inspect, modify, and process data. The user can account for variations in thermal conductivity with depth, responses from each thermistor, disruptions associated with probe insertion, and sensitivities to unknown parameters, leading to reliable and nuanced heat flow analyses.